What are some hidden advantages of logo signage?

Release Time : 2025-08-27

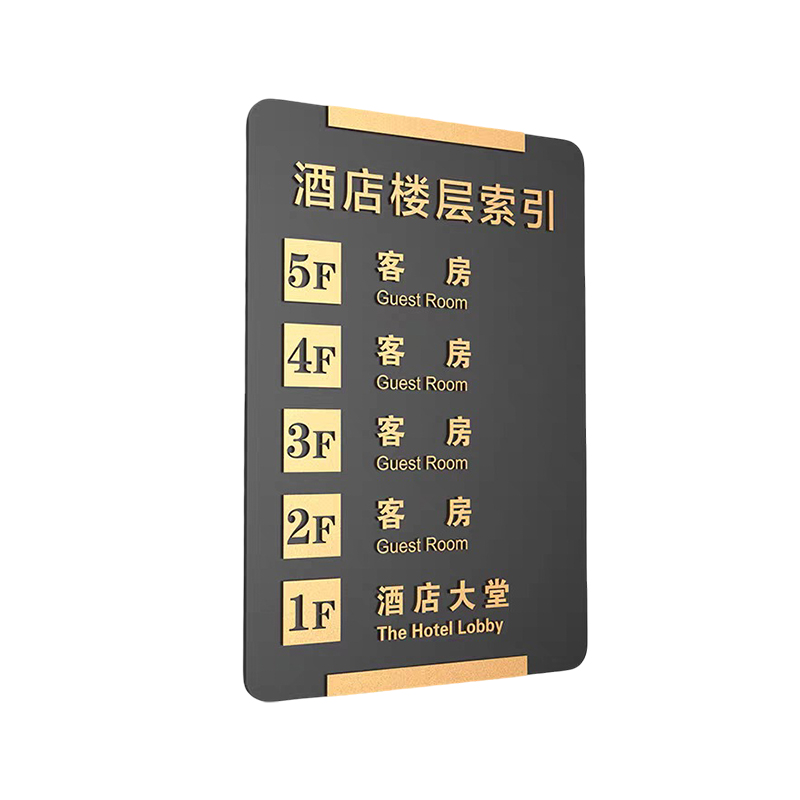

In public spaces, logo signage serves as a silent guide for information transmission, and its design directly impacts user experience and venue operational efficiency. Traditional logo signage often suffers from fragile materials, crude craftsmanship, and limited functionality, making it difficult to meet the complex demands of modern environments for durability, aesthetics, and practicality. However, logo signage, based on new materials such as SUS304 stainless steel, aluminum, and acrylic glass, combined with cutting-edge technologies like fiber laser cutting and intelligent lighting control, is reshaping the industry with its multi-dimensional advantages. The following highlights five lesser-known core advantages of logo signage, focusing on material performance, precision craftsmanship, and adaptability to specific scenarios.

1. Super Weather-Resistant Materials: A Lifespan Revolution from "Short-Term Use" to "Lifelong Maintenance"

1. Super Weather-Resistant Materials: A Lifespan Revolution from "Short-Term Use" to "Lifelong Maintenance"

Traditional logo signage, often made of wood, plastic, or ordinary metal, is susceptible to environmental damage, leading to deformation, fading, and even breakage. The new generation of logo signage achieves breakthrough durability through innovative materials:

SUS304 stainless steel base: This alloy, containing 18% chromium and 8% nickel, forms a dense oxide film in humid, acidic, and alkaline environments, offering corrosion resistance three times greater than that of ordinary stainless steel. Test data from an airport showed that after five years of use, the surface rust rate of outdoor logo signage was less than 0.5%, far below the industry standard of 5%.

Lightweight aluminum plate structure: With a density only one-third that of steel and reinforced with reinforced steel for enhanced rigidity, it can withstand force 5 winds (approximately 8-10 m/s) without deformation. After adopting aluminum plate signage at a high-speed rail station, the annual maintenance frequency has been reduced from 12 to two.

Acrylic transparent plate protection: With a light transmittance exceeding 92%, a surface hardness of 3H (pencil hardness), and impact resistance 16 times that of glass, a hospital's wayfinding system maintained a light transmittance of over 90% even after three years of use, scratches on the transparent plate were less than 0.1 mm deep.

Case study: The outdoor signage at a supermarket in a coastal city, constructed from stainless steel and acrylic, has survived six years of typhoon and salt spray damage. Annual cleaning alone restores the signage to pristine condition, reducing maintenance costs by 80% compared to traditional materials.

2. Precision Craftsmanship: Elevating the Experience from "Flat Display" to "3D Interactive"

Traditional logo signage relies on manual cutting and inkjet printing, resulting in issues such as edge burrs, color deviation, and blurred text. The next-generation logo signage achieves millimeter-level precision through digital processes:

Fiber laser cutting technology: Utilizing a high-energy-density beam to melt the material, the cutting slit width is less than 0.1mm (compared to approximately 1mm for traditional plasma cutting), resulting in smooth edges without the need for secondary polishing. The curved signage at an airport's baggage claim hall is laser-cut to achieve a 5mm radius, minimizing the risk of collisions for passengers.

Intelligent Welding and Bending: Automated welding using a robotic arm ensures weld seam strength exceeding 90% of the parent material. A CNC bending machine achieves 1° precision control, ensuring structural stability for complex signage. A subway station's custom-shaped signage, precisely bent to a 120° angle, offers ergonomic viewing angles while saving 30% space.

Text Engraving and Hollowing: A CO₂ laser engraver can create 0.2mm-wide lines on 0.5mm-thick stainless steel, achieving text clarity of 300 DPI (compared to 72 DPI for traditional silk-screen printing). A museum's cultural relic information signage uses hollowing technology to combine text and images, creating a three-dimensional projection effect under backlighting, increasing visitor engagement by 40%.

Technical Breakthrough: Signage with built-in LEDs utilizes light guide plate homogenization technology. Laser dot arrays transform point light sources into surface light sources, achieving brightness uniformity exceeding 90%, eliminating the "spot" problem associated with traditional light boxes.

3. Intelligent Lighting Systems: A Functional Transition from "Passive Lighting" to "Active Guidance"

Traditional logo signage relies on external light sources or simple built-in bulbs, which suffer from insufficient brightness, high energy consumption, and the inability to dynamically adjust. The new generation of signage features intelligent upgrades using LED technology:

Color temperature customization: Supports stepless adjustment from 2700K (warm light) to 6500K (cold light) to suit different scenarios. For example:

Hospital corridors use 4000K neutral light to reduce patient anxiety; mall promotion areas use 6500K cool white light to enhance product appeal; and library shelf signs use 3000K warm light to create a tranquil reading atmosphere.

Dynamic Guidance Mode: A built-in microcontroller programmably controls the flashing frequency and color of the light, enabling functions such as emergency evacuation and route guidance. Signage at an airport security checkpoint uses a green light that flashes during peak hours, shortening queue times by 25%.

Energy-saving and environmentally friendly design: Using high-efficiency LED chips (>120 lm/W) and intelligent sensor modules, the system automatically dims to 30% when unoccupied, reducing energy consumption by 70% compared to traditional fluorescent lamps. A school classroom signage system saves 12,000 kWh of electricity annually, equivalent to reducing carbon emissions by 9.6 tons.

Data support: After a large supermarket upgraded its smart signage system, customer navigation time decreased from an average of 4.2 minutes to 1.8 minutes, and sales increased by 8% due to the improved shopping experience.

4. Full-Scene Customization: Deep Integration from "Standard Parts" to "Spatial Language"

Traditional logo signage has a fixed size and single function, making it difficult to adapt to complex spatial needs. The new generation of signage achieves "one sign for multiple uses" through modular design:

Infinite Size Customization: Supports full-scale coverage from 10cm×10cm (desktop signage) to 10m×3m (outdoor wayfinding wall). Finite element analysis is used to optimize structural strength to ensure deformation-free even for large signs.

Multi-Material Combination: For example:

Stainless steel + acrylic: Suitable for high-end shopping mall brand walls, combining quality and light transmittance.

Aluminum + Printed Film: Suitable for temporary exhibitions, reducing costs by 60% and enabling quick image changes.

Double-layer acrylic: Intercalates an electronic ink screen to enable dynamic content updates (such as train schedules at stations).

Accessible Design: According to the "Accessible Design Specification," signage text height must be ≥30mm, the Chinese-English font size ratio must be 1:0.7, and the Braille dot height must be 0.8mm, ensuring barrier-free access for people with disabilities. By optimizing the height and angle of signage, one hospital increased wheelchair user recognition from 70% to 95%.

Innovative Scenario: One airport is integrating signage with AR technology. Passengers can scan the QR code on the signage with their phones to overlay 3D route guidance on their screens, solving the problem of wayfinding in complex hubs.

5. Safety and Environmental Protection: Extending Value from "Compliance" to "Social Responsibility"

Traditional logo signage production processes involve pollution from welding fumes and paint exhaust, and some materials contain hazardous substances such as lead and mercury. The new generation of signage achieves sustainable development through green manufacturing:

Environmentally friendly materials: SUS304 stainless steel and acrylic panels are both ROHS certified, with lead, cadmium, and other heavy metal content less than 0.01%.

Clean production process: Laser cutting replaces mechanical stamping, reducing metal dust emissions; water-based paint spraying replaces solvent-based paint, reducing VOC emissions by 90%.

Recyclable design: The signage features a snap-on structure, allowing 90% of its components to be recycled after disassembly. One company recycles old signage and remelts the stainless steel, saving over 500,000 yuan in raw material costs annually.

Social impact: After adopting environmentally friendly signage across one city's entire subway network, volatile organic compound emissions have been reduced by 12 tons annually, equivalent to the carbon sequestration capacity of planting 60,000 trees.

The "Invisible Revolution" of Logo Signage

The "Invisible Revolution" of Logo Signage

From material durability to precision craftsmanship, from intelligent interaction to full-scenario adaptability, the new generation of Logo Signage is quietly reshaping the way information is conveyed in public spaces. Behind this is the interdisciplinary integration of materials science, optical engineering, and human-computer interaction: the corrosion resistance of stainless steel, the plasma physics of laser cutting, and the spectrum control technology of LEDs... Each breakthrough reflects a deep understanding of user experience. With the widespread adoption of 5G and IoT technologies, future logo signage will further integrate sensors and data analysis capabilities, becoming a "thinking" information node in smart cities. This silent revolution is elevating every sign from a "functional accessory" to a "core carrier of spatial language."

Traditional logo signage, often made of wood, plastic, or ordinary metal, is susceptible to environmental damage, leading to deformation, fading, and even breakage. The new generation of logo signage achieves breakthrough durability through innovative materials:

SUS304 stainless steel base: This alloy, containing 18% chromium and 8% nickel, forms a dense oxide film in humid, acidic, and alkaline environments, offering corrosion resistance three times greater than that of ordinary stainless steel. Test data from an airport showed that after five years of use, the surface rust rate of outdoor logo signage was less than 0.5%, far below the industry standard of 5%.

Lightweight aluminum plate structure: With a density only one-third that of steel and reinforced with reinforced steel for enhanced rigidity, it can withstand force 5 winds (approximately 8-10 m/s) without deformation. After adopting aluminum plate signage at a high-speed rail station, the annual maintenance frequency has been reduced from 12 to two.

Acrylic transparent plate protection: With a light transmittance exceeding 92%, a surface hardness of 3H (pencil hardness), and impact resistance 16 times that of glass, a hospital's wayfinding system maintained a light transmittance of over 90% even after three years of use, scratches on the transparent plate were less than 0.1 mm deep.

Case study: The outdoor signage at a supermarket in a coastal city, constructed from stainless steel and acrylic, has survived six years of typhoon and salt spray damage. Annual cleaning alone restores the signage to pristine condition, reducing maintenance costs by 80% compared to traditional materials.

2. Precision Craftsmanship: Elevating the Experience from "Flat Display" to "3D Interactive"

Traditional logo signage relies on manual cutting and inkjet printing, resulting in issues such as edge burrs, color deviation, and blurred text. The next-generation logo signage achieves millimeter-level precision through digital processes:

Fiber laser cutting technology: Utilizing a high-energy-density beam to melt the material, the cutting slit width is less than 0.1mm (compared to approximately 1mm for traditional plasma cutting), resulting in smooth edges without the need for secondary polishing. The curved signage at an airport's baggage claim hall is laser-cut to achieve a 5mm radius, minimizing the risk of collisions for passengers.

Intelligent Welding and Bending: Automated welding using a robotic arm ensures weld seam strength exceeding 90% of the parent material. A CNC bending machine achieves 1° precision control, ensuring structural stability for complex signage. A subway station's custom-shaped signage, precisely bent to a 120° angle, offers ergonomic viewing angles while saving 30% space.

Text Engraving and Hollowing: A CO₂ laser engraver can create 0.2mm-wide lines on 0.5mm-thick stainless steel, achieving text clarity of 300 DPI (compared to 72 DPI for traditional silk-screen printing). A museum's cultural relic information signage uses hollowing technology to combine text and images, creating a three-dimensional projection effect under backlighting, increasing visitor engagement by 40%.

Technical Breakthrough: Signage with built-in LEDs utilizes light guide plate homogenization technology. Laser dot arrays transform point light sources into surface light sources, achieving brightness uniformity exceeding 90%, eliminating the "spot" problem associated with traditional light boxes.

3. Intelligent Lighting Systems: A Functional Transition from "Passive Lighting" to "Active Guidance"

Traditional logo signage relies on external light sources or simple built-in bulbs, which suffer from insufficient brightness, high energy consumption, and the inability to dynamically adjust. The new generation of signage features intelligent upgrades using LED technology:

Color temperature customization: Supports stepless adjustment from 2700K (warm light) to 6500K (cold light) to suit different scenarios. For example:

Hospital corridors use 4000K neutral light to reduce patient anxiety; mall promotion areas use 6500K cool white light to enhance product appeal; and library shelf signs use 3000K warm light to create a tranquil reading atmosphere.

Dynamic Guidance Mode: A built-in microcontroller programmably controls the flashing frequency and color of the light, enabling functions such as emergency evacuation and route guidance. Signage at an airport security checkpoint uses a green light that flashes during peak hours, shortening queue times by 25%.

Energy-saving and environmentally friendly design: Using high-efficiency LED chips (>120 lm/W) and intelligent sensor modules, the system automatically dims to 30% when unoccupied, reducing energy consumption by 70% compared to traditional fluorescent lamps. A school classroom signage system saves 12,000 kWh of electricity annually, equivalent to reducing carbon emissions by 9.6 tons.

Data support: After a large supermarket upgraded its smart signage system, customer navigation time decreased from an average of 4.2 minutes to 1.8 minutes, and sales increased by 8% due to the improved shopping experience.

4. Full-Scene Customization: Deep Integration from "Standard Parts" to "Spatial Language"

Traditional logo signage has a fixed size and single function, making it difficult to adapt to complex spatial needs. The new generation of signage achieves "one sign for multiple uses" through modular design:

Infinite Size Customization: Supports full-scale coverage from 10cm×10cm (desktop signage) to 10m×3m (outdoor wayfinding wall). Finite element analysis is used to optimize structural strength to ensure deformation-free even for large signs.

Multi-Material Combination: For example:

Stainless steel + acrylic: Suitable for high-end shopping mall brand walls, combining quality and light transmittance.

Aluminum + Printed Film: Suitable for temporary exhibitions, reducing costs by 60% and enabling quick image changes.

Double-layer acrylic: Intercalates an electronic ink screen to enable dynamic content updates (such as train schedules at stations).

Accessible Design: According to the "Accessible Design Specification," signage text height must be ≥30mm, the Chinese-English font size ratio must be 1:0.7, and the Braille dot height must be 0.8mm, ensuring barrier-free access for people with disabilities. By optimizing the height and angle of signage, one hospital increased wheelchair user recognition from 70% to 95%.

Innovative Scenario: One airport is integrating signage with AR technology. Passengers can scan the QR code on the signage with their phones to overlay 3D route guidance on their screens, solving the problem of wayfinding in complex hubs.

5. Safety and Environmental Protection: Extending Value from "Compliance" to "Social Responsibility"

Traditional logo signage production processes involve pollution from welding fumes and paint exhaust, and some materials contain hazardous substances such as lead and mercury. The new generation of signage achieves sustainable development through green manufacturing:

Environmentally friendly materials: SUS304 stainless steel and acrylic panels are both ROHS certified, with lead, cadmium, and other heavy metal content less than 0.01%.

Clean production process: Laser cutting replaces mechanical stamping, reducing metal dust emissions; water-based paint spraying replaces solvent-based paint, reducing VOC emissions by 90%.

Recyclable design: The signage features a snap-on structure, allowing 90% of its components to be recycled after disassembly. One company recycles old signage and remelts the stainless steel, saving over 500,000 yuan in raw material costs annually.

Social impact: After adopting environmentally friendly signage across one city's entire subway network, volatile organic compound emissions have been reduced by 12 tons annually, equivalent to the carbon sequestration capacity of planting 60,000 trees.

From material durability to precision craftsmanship, from intelligent interaction to full-scenario adaptability, the new generation of Logo Signage is quietly reshaping the way information is conveyed in public spaces. Behind this is the interdisciplinary integration of materials science, optical engineering, and human-computer interaction: the corrosion resistance of stainless steel, the plasma physics of laser cutting, and the spectrum control technology of LEDs... Each breakthrough reflects a deep understanding of user experience. With the widespread adoption of 5G and IoT technologies, future logo signage will further integrate sensors and data analysis capabilities, becoming a "thinking" information node in smart cities. This silent revolution is elevating every sign from a "functional accessory" to a "core carrier of spatial language."